Buildaline

Everything you need to build your own brake and clutch lines

No pre alignment required

Easy to install

• Stainless steel braided PTFE lined hose

• Line length from 200mm to 1700mm

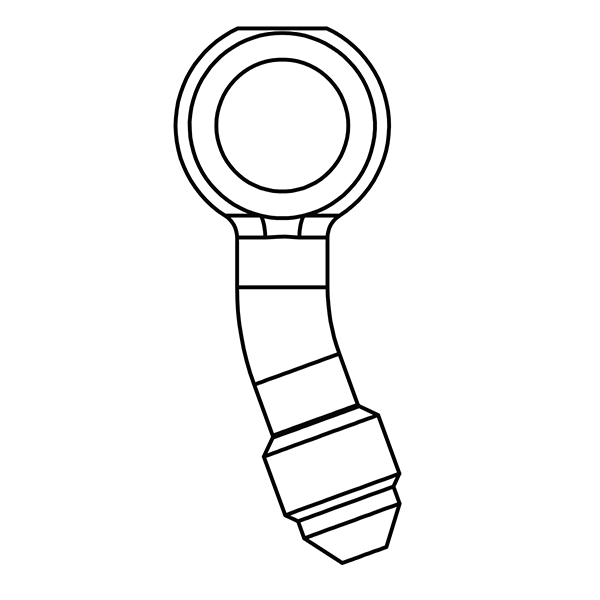

• S/S screw fit banjos in 20°, 45°, 70°, 90° and straight

• Hose assemblies pressure tested to 2000 PSI

• FMVSS 106 and DOT compliant

PLEASE NOTE

Buildaline custom hose lengths are made to order.

Therefore, we cannot offer a refund for any incorrectly ordered length.

1. Select fittings

Select the appropriate fittings, adaptors and T-Pieces. Fittings can be aligned on installation.

SBK592-03C

Straight - 10mm hole

SBK593-03C

20° - 10mm hole

SBK597-03C

20° (Side bend) - 10mm hole

SBK593R-03C

20°

(Compound right)

SBK593L-03C

20°

(Compound left)

SBK594-03C

45° - 10mm hole

SBK594L-03C

45° (Compound left) - 10mm hole

SBK594R-03C

45° (Compound right) - 10mm hole

SBK570-03C

70° - 10mm hole

SBK599-03C

90° - 10mm hole

SBK599S-03C

90° (side) - 10mm hole

2. Select required hose length

Buildaline hoses are available in lengths from 200mm to 1700mm in 25mm increments. Hose lengths are calculated excluding fittings.

(see 1st picture)

To calculate the required hose length with banjo fittings, measure your existing hose banjo centre to banjo centre and subtract 90mm. If you don’t have an existing hose, remember to add 90mm (45mm at each end) to calculate the complete assembly.

(see 2nd picture)

*Remember to consider suspension travel when selecting hose lengths.

3. Select bolts

SBK992-03-31SC

Single banjo bolt M10 (Brembo)

SBK992-03-32C

Single banjo bolt M10 x 1.25

SBK993-03-31SC

Double banjo bolt M10 (Brembo)

SBK993-03-32C

Double banjo bolt M10 x 1.25

SBK992-31BNSC

Single banjo bolt M10 (Brembo) with bleed nipple

4. Select ancillaries

Select the appropriate fittings, adaptors and T-Pieces.

SBK305-03-31C

M10 x 1.25

SBK305-03-32C

M10 x 1.00

5130-03C

3/8 JIC T-Piece

SBKPLCC-05

P-Clip

44516

Copper washer M10

(Pack of 10)

Installation guide

STEP 01

Fit in place the banjo adaptors with the bolts and thecorrect amount of washers. Our recommended torquesetting for this is 14 – 24 ft/lbs. This torque setting isadvisory for the fittings, NOT for your master cylinderor calipers. Care must be taken not to damage either your master cylinder or calipers. Please also ensure that you have chosen the correctthreaded bolt for your application.

STEP 02

Locate the correct length hose. Route the hose safely,ensuring that it cannot be damaged by daily use of yourbike, when the steering is at full lock. Use tube clampsif necessary (SBKPLCC-05) to help with the routing.

STEP 03

Screw the hose onto the banjo adaptors, making surethat it has been fully tightened.

Tip - As a rough guide, finger tight then a ¼ turn will give you 14 ft/lbs.

STEP 04

P-Clips (SBKPLCC-05) are available to ensure that yourhoses are routed correctly.

STEP 05

Bleed your brakes correctly and carefully following anyspecial bleeding sequence as recommended in yourbike manual. Use the manufactures recommended brakefluid. Goodridge recommend a high quality DOT 4 fluid

Brake FluidSTEP 06

TEST FOR ANY LEAKS

STEP 07

After using your bike for the first time, we recommend that you give your brakes and fittings a thoroughinspection to check for any leaks.

If any leaks are present, tighten your fittings and repeat step 5 once more.